Bowmore encourages responsible drinking. You must be of legal purchase age to enter this website. Alcohol should be consumed in moderation. By entering this website, you are agreeing to our Terms and Conditions, Privacy Policy and Cookie Policy.

Our Scotch Whisky Making Process

our process

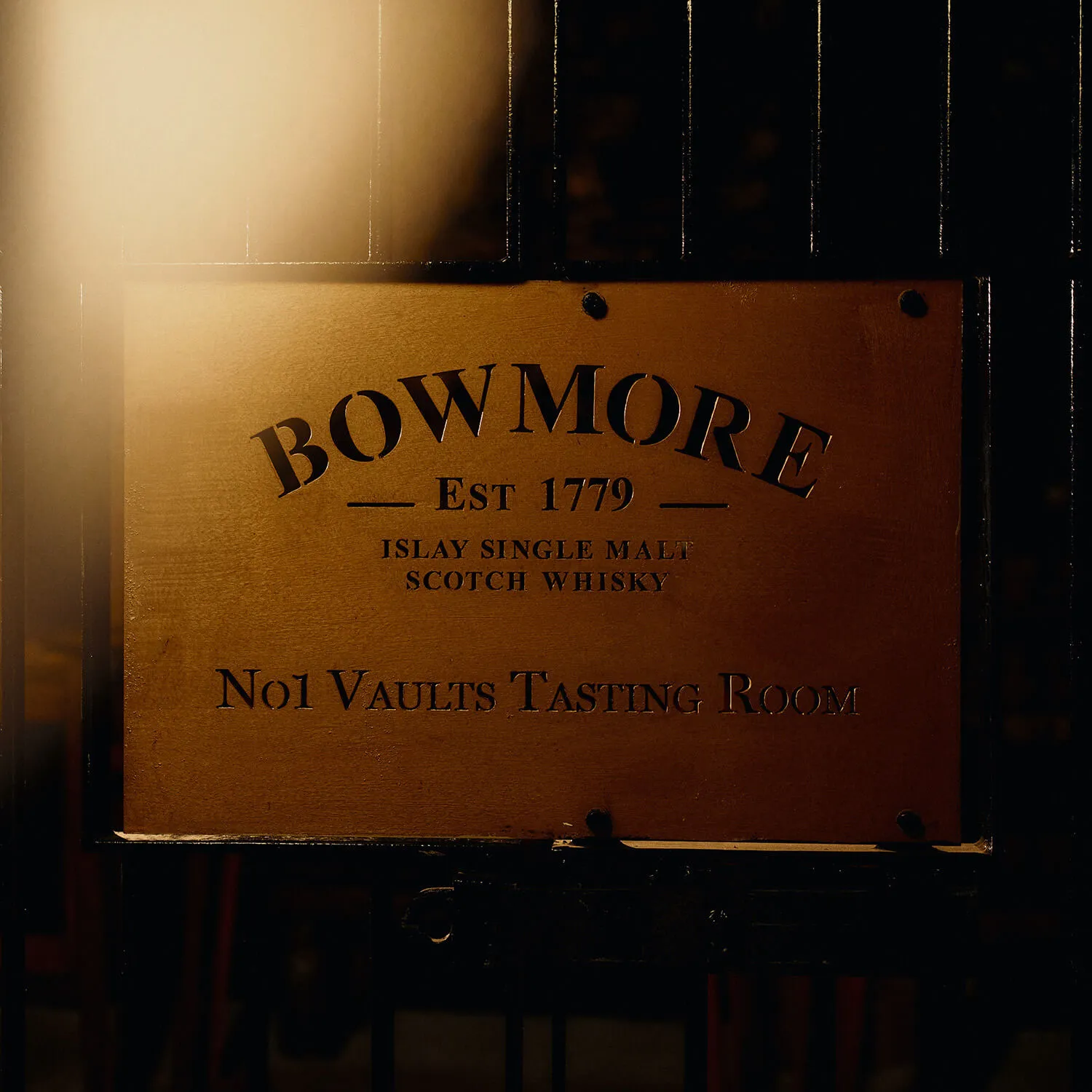

Since 1779 we have crafted our expressive, multi-dimensional single malt, surrounded by the untamed beauty of our island home. As the centuries have passed a few things have changed in our whisky making process. However, the processes we follow in creating Bowmore single malt Scotch whisky are but a gently refined evolution of what has always been. Indeed, to walk into our No1 vault on the shores of Loch Indaal is to walk back in time.

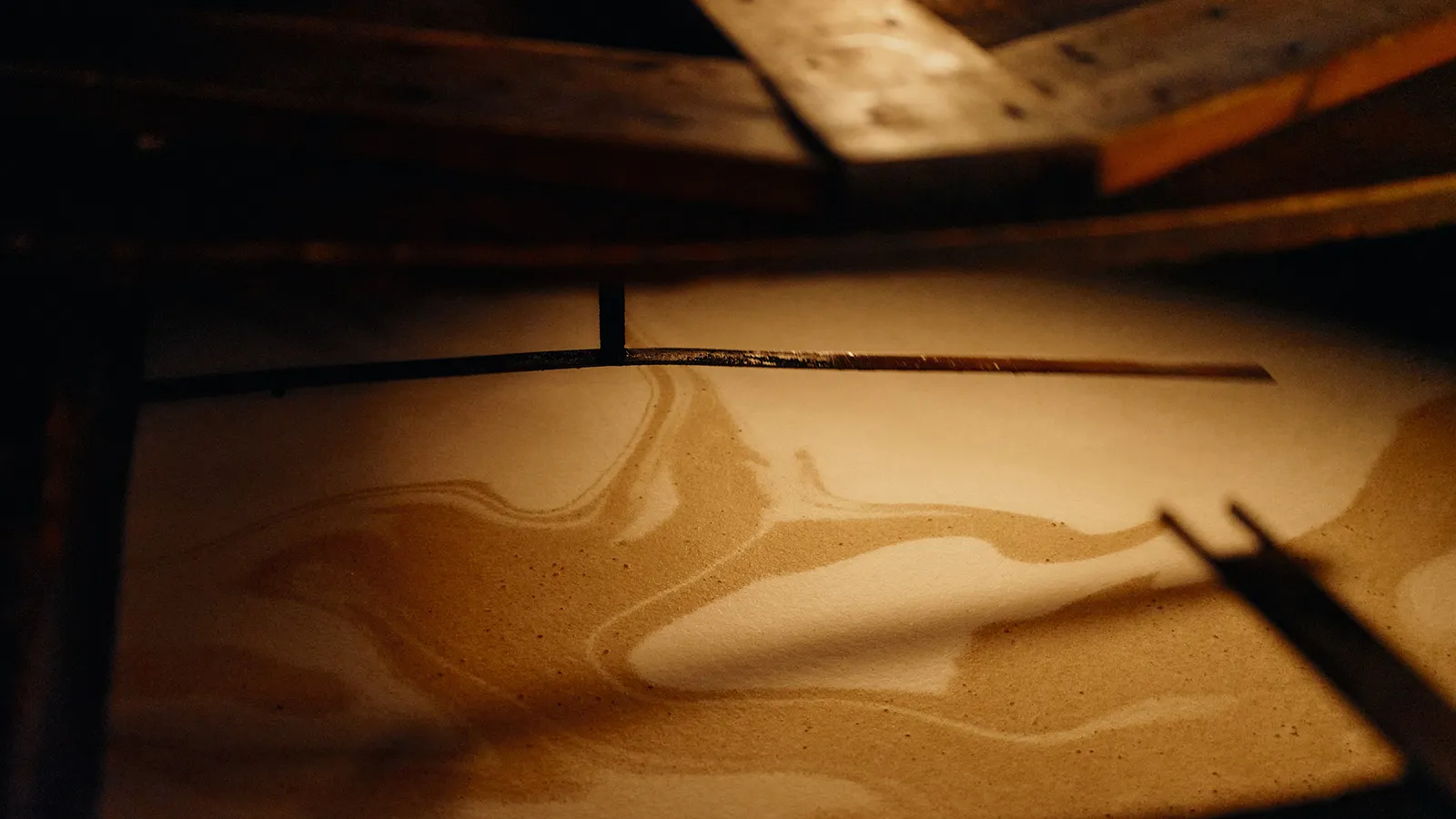

Floor Malting

We believe that excellence in whisky making means leaving nothing to chance. Maintaining our own malt barn enables us to offer discerning drinkers the unmistakable hand-crafted experience for which we are recognised throughout the world. Day and night we return to the barn at four hour intervals to turn our barley by hand, keeping an experienced and watchful eye on its progress.

The Kiln

Our kiln at the Bowmore Distillery is a sight to behold, and integral to our whisky making process. To be near it is to experience a journey of the senses. It contains two furnaces, whose rich smoke billows upward and through a mesh floor. There it envelopes, and dries, the malt spread out upon it. The peat that is introduced at this crucial drying stage helps give Bowmore single malt whisky the signature taste for which it is celebrated.

Peat is an organic fuel that is commonly found in bogs across Islay and many of the other islands around Scotland. It's made from compressed layers of organic material such as grass, heather and moss, and formed over thousands of years.

The mill

Our beautifully engineered Porteus Malt Mill is an exemplar of the timeless value of quality. For six decades it has operated almost non-stop, tirelessly grinding clean grain down to grist. The process is highly efficient, generating no waste product.

the mash house

Within the Mash House is the Mash Tun. A vast hot water pot heated by two copper kettles, it dates back to the second world war. In the Mash Tun grist and hot water are mixed, creating a dark coloured liquid with a rich, powerful, malty aroma, unforgettable to those fortunate enough to have experienced it.

The tun room

Our two-storey tall Oregon Pine Washbacks are where the fermentation process takes place. The Tun room houses six of these imposing structures, which froth dramatically as yeast converts the sugars to alcohol. The washbacks also serve as a history lesson, with the names of prominent figures or families from the annals of the Bowmore Distillery commemorated atop each one.

The stillhouse

The heart of the Bowmore Distillery, it is here, within four stills, that the spirit that will eventually become whisky is made. Through a meticulous and precisely choreographed series of processes conducted across successive sills, heat and time separate out the alcoholic vapour. The prized Heart of the Run portion of the vapour drawn off by our Stillman, is the only cut that fills our casks.

Maturation

Everything we do to create Bowmore single malt Scotch whisky is tended to with the utmost importance. However it is during the crucial stage of maturation that its complex, multi-layered persona is crafted.